Industrial Paint Curing Ovens

Paint curing ovens are specifically designed to heat paint to the point where the curing reaction can occur. This reaction creates a stronger bond between the paint and surface making it more durable and resistant to scratches.

Model Guide

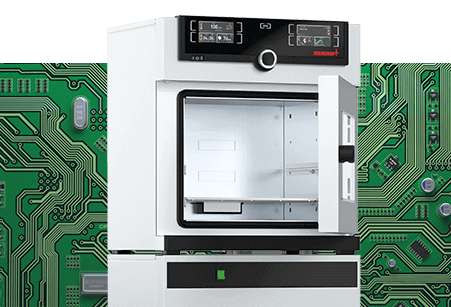

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

UN

Natural Convection Oven

Memmert’s natural convection ovens are designed to reach temperatures up to 300°C efficient for complex processes with sensitive loads, or routine drying and sterilization tasks.

VO

Vacuum Oven

Vacuum drying ovens with direct heating within each adjustable thermoshelf provides optimum temperature distribution and fast vacuum drying capability.

VOcool

Low Temperature Vacuum Oven

Low-temperature vacuum drying enables pharmaceutical or food labs to gently dry bacteria and starter cultures in the cooled vacuum oven VOcool.

How Paint Curing Ovens Work

Paint curing is the process of removing all moisture from paint, allowing it to fully bond with the material it has been placed on. During the curing cycle, heat initiates paint polymerization, a chemical reaction causing the coating to cross-link and permanently bond to the substrate. In paint baking ovens, controlled heat accelerates this process, resulting in a harder, more chemically resistant finish compared to air-dried coatings.

The curing process hardens the paint, making it more durable and resistant to wear and tear. Memmert’s industrial curing ovens can be easily set at the optimum temperature for your paint and efficiently cure paint to make it ready for use.

Our curing ovens can cure a variety of paints including:

- Acrylic paints

- Latex paints

- Oil-based paints

Industrial Paint Curing Ovens for Manufacturing Applications

Industrial paint curing ovens are essential in manufacturing environments where consistent heat and precise temperature control are required for proper paint polymerization. Electric curing ovens provide uniform heat distribution, making them ideal for industrial facilities demanding repeatable results, energy efficiency and compliance with production standards across high-volume operations.

Industrial paint curing ovens are commonly used for:

- Automotive paint curing and paint baking applications

- Metal parts and fabricated component coatings

- Ceramic coating and high-temperature surface finishes

- Varnish and protective clear coat curing

- Industrial paint polymerization requiring precise thermal control

- Electric curing oven applications in clean or regulated facilities

Temperature Control & Uniform Heating

Memmert vacuum and convection ovens for paint curing offer consistent airflow and temperature uniformity, ensuring even curing across all coated surfaces. Precise temperature control from 5 °C to 300 °C minimizes defects such as blistering, under-curing or uneven finishes, making industrial paint curing ovens essential for high-quality production output.

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB