Decarboxylation Ovens

Decarboxylation ovens are used to cause a chemical reaction that replaces a carboxyl group with a hydrogen atom. Decarboxylation ovens are necessary for many industries, including CBD production, as standard ovens are not as precise and can easily burn fine powders and flowers.

Model Guide

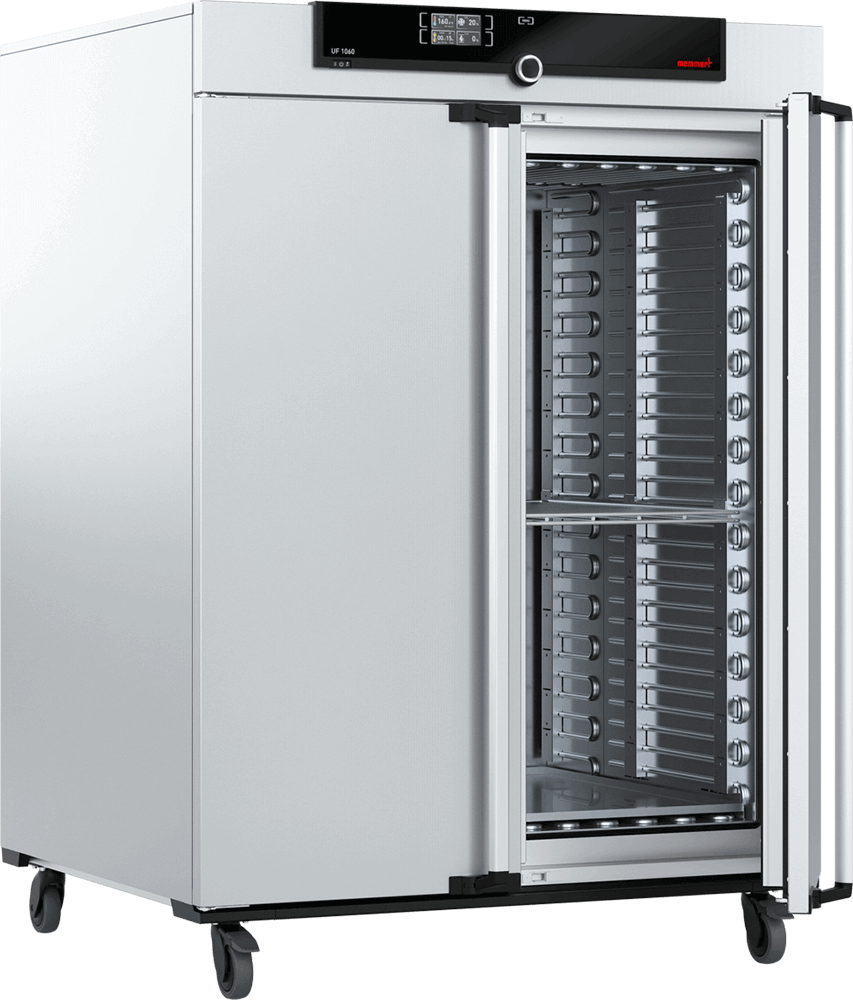

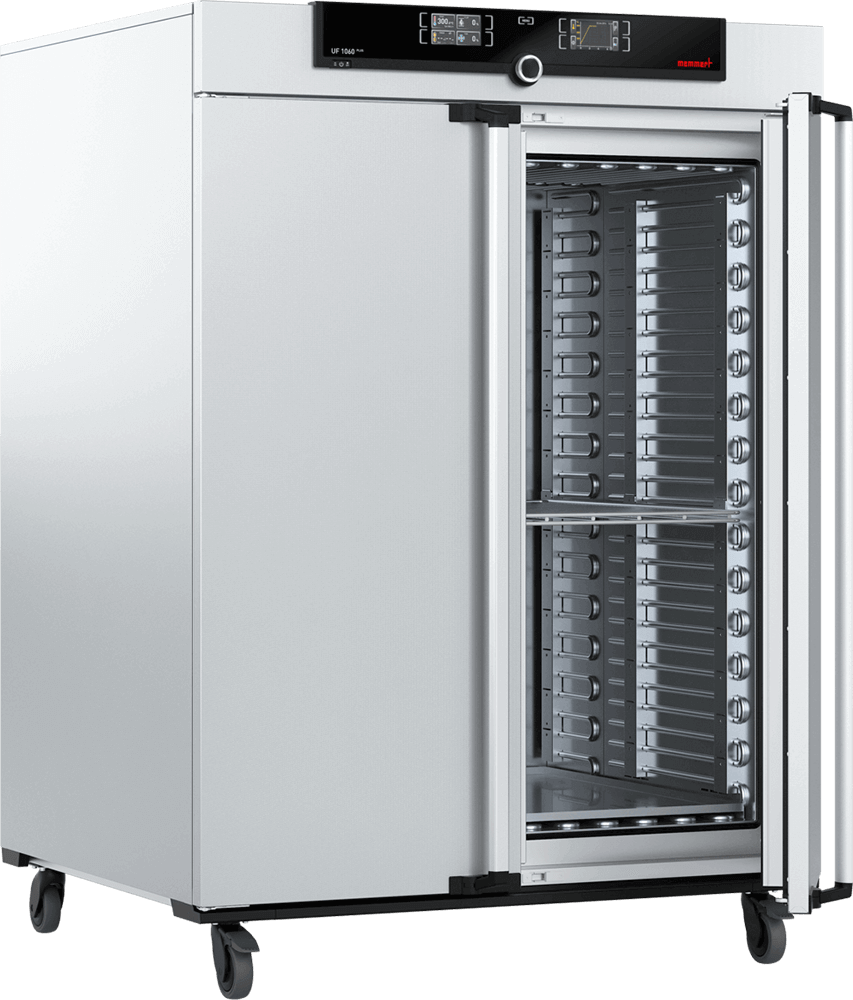

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

Decarboxylation Oven Uses

Decarboxylation ovens are used to preserve a plant’s quality and potency via a consistent, controlled environment. A decarboxylation oven works by heating plant materials according to customized specifications to eliminate carboxylic acid groups from organic compounds.

Decarboxylation achieves maximum cannabinoid activation by converting inactive cannabinoids (THCA, CBDA) to their active forms, THC and CBD.

Importance of decarboxylation ovens

Decarboxylation is important to preserving the integrity and potency of plant materials to produce high-quality cannabis and hemp products in a variety of applications. Decarboxylation is an efficient way to preserve large amounts of plant materials and to prevent them from decreasing in quality or potency. Decarboxylation also increases the versatility of cannabis or hemp, broadening their use to edibles, tinctures and topicals.

Uniform heating, stainless steel and built-in sensors for temperature make Memmert decarboxylation ovens stand out in labs and other industries. Our air exchange rates and air flap positions are electronically controllable (programmable via our AtmoCONTROL software for only models with TwinDISPLAY).

Programmable Lab Equipment

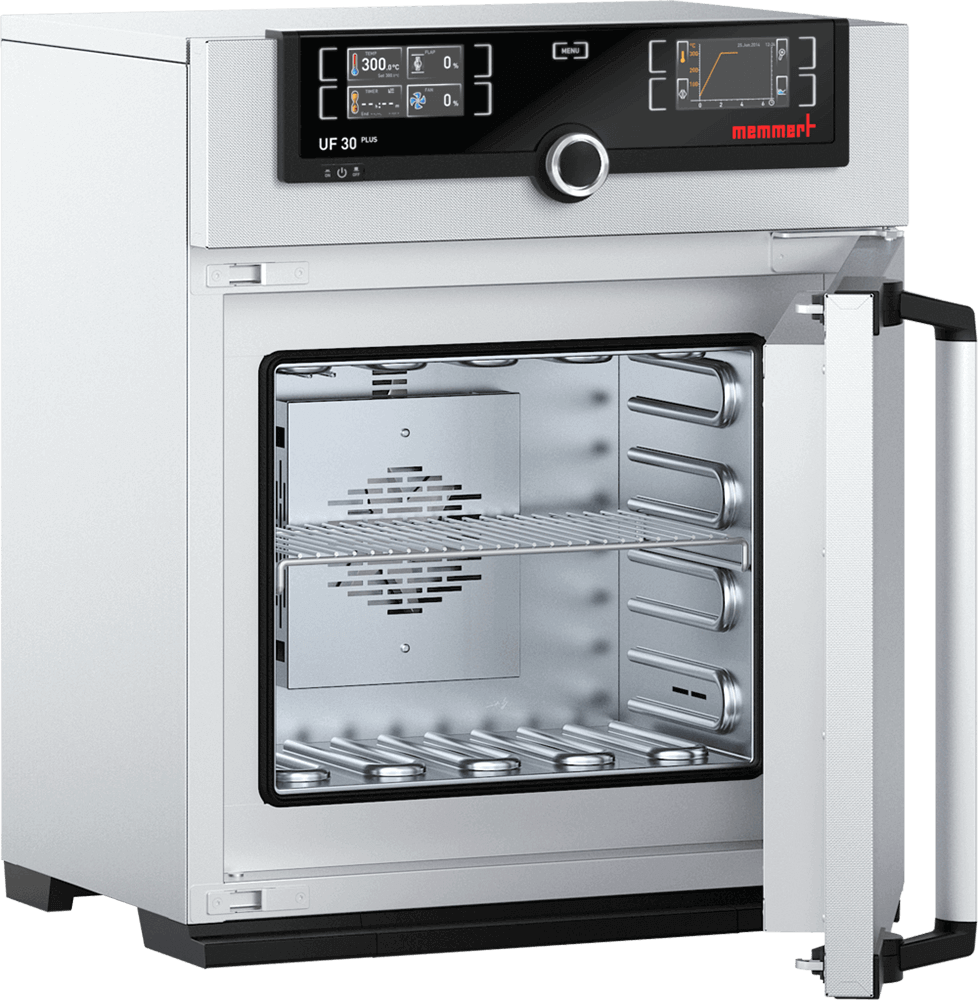

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB