Solder Reflow Ovens

Solder reflow ovens are used in the manufacturing and repair processes of PCB boards to reform the connections between surface mount devices (SMDs) and the circuit board when they are too small to be hand-soldered.

How solder reflow ovens work

Reflow soldering attaches electronic components to a circuit board. Solder paste is applied to the board, then the board is heated slowly and steadily by a reflow oven, melting the paste and bonding electrical components to the board while protecting the fragility of each component. Reflow soldering is fast, efficient and reliable. With reflow soldering, small and densely arranged components can be used in PC boards.

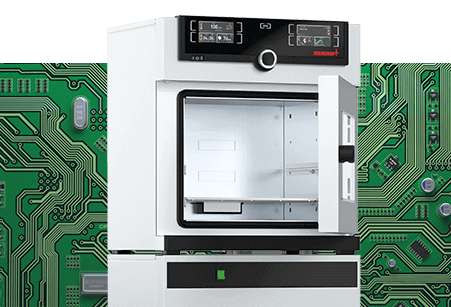

Memmert offers high-quality programmable ovens for reflow soldering on PCB boards, with models ranging from compact benchtop units to large, 1060-liter standalone systems on castors.

Model Guide

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

UN

Natural Convection Oven

Memmert’s natural convection ovens are designed to reach temperatures up to 300°C efficient for complex processes with sensitive loads, or routine drying and sterilization tasks.

VO

Vacuum Oven

Vacuum drying ovens with direct heating within each adjustable thermoshelf provides optimum temperature distribution and fast vacuum drying capability.

Precision-Controlled Reflow Soldering for PCB Manufacturing

Memmert solder reflow ovens deliver repeatable heating profiles for reliable surface mount technology (SMT) assembly and PCB repair. Whether you're working with compact prototypes or high-volume circuit boards, our ovens support consistent reflow across a range of thermal profiles. Each unit offers uniform temperature distribution and programmable controls to protect components during every phase of the reflow process.

Our soldering ovens are trusted by manufacturers, electronics labs and R&D facilities requiring fast cycle times and precise heat control. Choose from a wide range of chamber volumes (7 to 1060 liters) and display/control configurations including singleDISPLAY, TwinDISPLAY and AtmoCONTROL for advanced programming and data logging.

Reflow Ovens for Every Application

Memmert offers solder reflow ovens in vacuum, natural convection and forced circulation models to support everything from basic thermal bonding to complex multilayer PCB reflow work. Available in benchtop and freestanding configurations, our reflow ovens are engineered to support:

- Consistent solder reflow on densely packed boards

- Lead-free and low-temp soldering processes

- Thermal cycling for board reliability testing

- Precise ramp-up, soak and cooling stages

- Multiboard or batch processing with uniform heat

We build solder reflow ovens with a corrosion-resistant stainless steel chamber and back all models with a 3-year manufacturer's warranty.

Contact Memmert USA to find the right solder reflow oven for your electronics lab or production line.

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB