HPP2200eco Memmert Constant Climate Chambers

Former Models: HPP2200

Overview

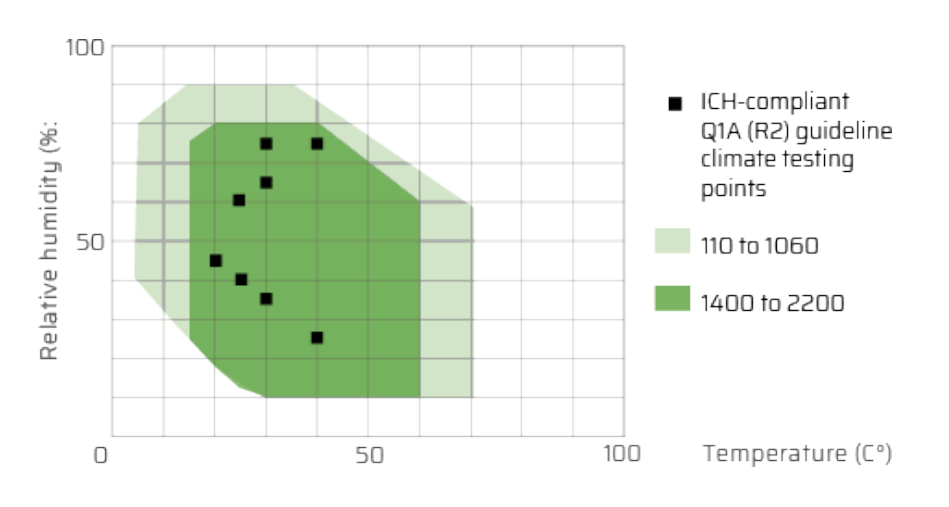

HPP 2200 Memmert environmental chambers guarantee the perfect atmosphere for climate and temperature tests. Our constant climate chamber is tailored to environmental simulation, material testing and stability testing in accordance with the ICH guidelines. Let us help you build the perfect environmental test chamber.

Contact us for customization options and pricing.

Features

Temperature & Humidity

Control technology

Safety, Standards, & Data

Interior & Exterior

Accessories

Publications

Temperature & Humidity

Temperature Specs:

- Setting temperature range:

without light, with humidity: +15 to +60 °C; without light, without humidity: 0 to +70 °C - Working temperature range:

without light, with humidity: +15 (at least 10 below ambient temperature) to +60 °C; without light, without humidity: 0 (at least 20 below ambient temperature) to +70 °C - Setting accuracy temperature:

0.1°C - Temperature sensor:

2 Pt100 sensors Class A in 4-wire-circuit, mutually monitoring and taking over the performance at the same temperature value

Humidity Specs:

- Setting range humidity:

10 – 90 % rh - Setting accuracy humidity:

0.5% - Humidity:

humidity supply with distilled water from external tank by self-priming pump - Humidification & Dehumidification:

humidification by hot steam generator; dehumidification by cold trap using the Peltier technology

Heating Concept:

- Peltier:

energy-saving Peltier heating-/cooling system integrated in the rear (heat pump principle)

Control technology

Control Technology:

- ControlCOCKPIT:

TwinDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with 2 high-definition TFT-color displays. - Language Setting:

German, English, Spanish, French, Polish, Czech, Hungarian - Adjustable Parameters:

Temperature (Celsius or Fahrenheit), relative humidity, program time, time zones, summertime/wintertime - Timer:

Digital backwards counter with target time setting, adjustable from 1 minute to 99 days - Function HeatBALANCE:

Adapting the distribution of the heating performance of the upper and lower heating circuit from -50 % to +50 % - Function SetpointWAIT:

The process time does not start until the set temperature is reached - Calibration:

Three freely selectable values each, temperature and humidity

Safety & Standards

Safety:

- Temperature control:

mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 10°C above nominal temperature - Temperature control:

over- and under temperature monitor TWW, protection class 3.3 or adjustable temperature limiter TWB, protection class 2, adjustable at the controller - AutoSAFETY:

additionally integrated over- and under temperature protection “ASF”, automatically following the setpoint value at a preset tolerance range, alarm in case of over- or under temperature, heating is switched off in case of overtemperature, the compressor in case of under temperature - Autodiagnostic system:

integral fault diagnostics for temperature and humidity control - Alarm:

with visual and acoustic alarm in case of over-/under temperature and under humidity, open door and empty water tank

Additional data

Electrical data

230 Volts

- 50/60 Hz, approx. 2000 W

Certifications

![]()

![]()

![]()

![]()

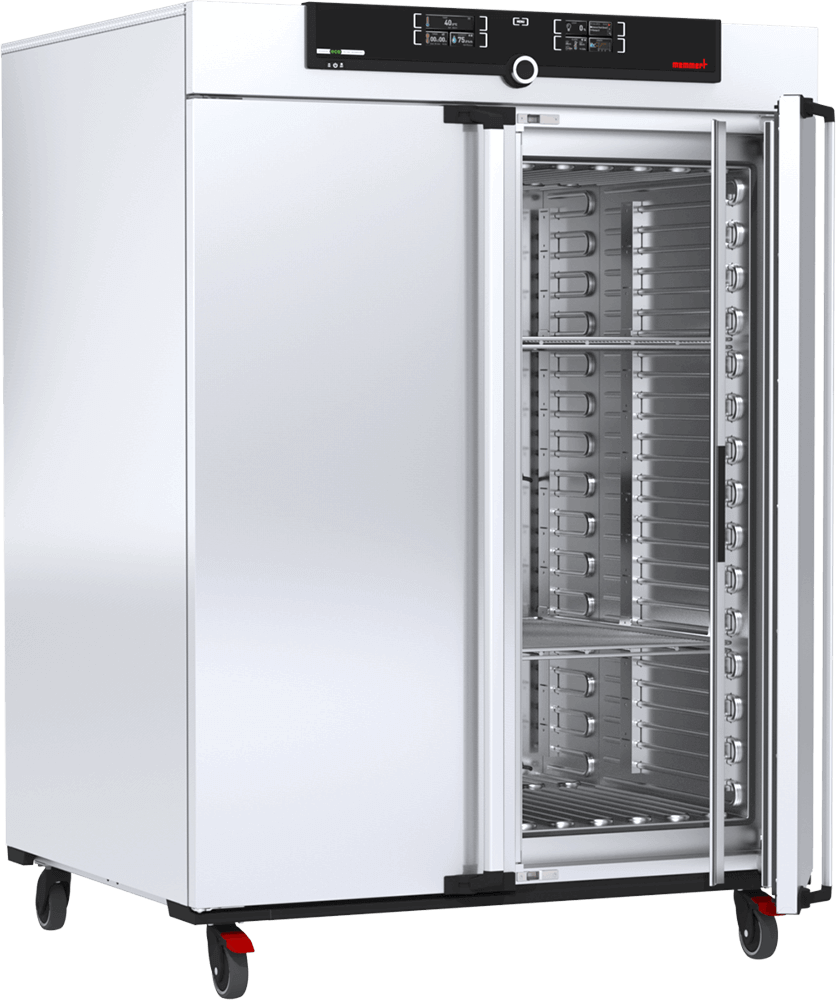

Interior & Exterior

Stainless Steel Interior

- Volume:

2140 l - Dimensions W x H x D in mm

w(A) x h(B) x d(C): 1972 x 1450 x 750 mm - Max. number of internals:

42 - Max. loading of chamber:

330 kgs - Max. loading per internal:

30 kgs

Textured Stainless Steel Casing

- Dimensions:

w x h x d : 2157 x 1913 x 905 mm (d +56mm door handle & +111mm Peltier element) - Housing:

rear zinc-plated steel - Installation:

on lockable castors, adjustable in height

Stainless Steel

For many years exterior textured stainless steel has been the unmistakable feature of Memmert ovens, incubators, and climate chambers in laboratory and light-industrial settings. Memmert equipment exemplifies functional design in its most elegant and hygienic form, while still being scratch resistant, robust and durable.

Stainless steel is the ideal material for temperature control chambers and heating baths. It is particularly corrosion-resistant, hygienic, robust and recyclable without question.

Wherever Memmert ovens and heating baths are used, the superiority of high-quality stainless steel is undeniable in comparison to others that utilize coated sheet steel, which can corrode very quickly when in constant use.

For the outer housing of all Memmert appliances, textured stainless steel is used (rear walls are zinc-plated sheets). The inner chamber, sliding shelves/grids, housing, interior basin and accessories for every heating bath, stainless steel of class W-St. 1.4301 (ASTM 304) is used. Since aggressive substances are frequently used in the vacuum drying oven, the inner chamber and thermoshelves are made of stainless-steel W-St. 1.4404 (ASTM 316L), and the tubing is made of stainless-steel W-St. 1.4571 (ASTM 316i).

Accessories

| Model sizes | 110 | 260 | 410 | 750 | 1060 | 1400 | 2200 |

|---|---|---|---|---|---|---|---|

| Stainless steel grids, electropolished | E20165 | E28891 | E28891 | E20182 | B41251 | B38955 | B38955 |

| Reinforced stainless steel grid, electropolished, max. loading 60 kg (model 750 with guide bars and fixing screws and only in connection with option K1) | E29767 | E29766 | E29766 | B32190 | B32550 | - | - |

| Perforated stainless steel shelves | B00325 | B29725 | B29725 | B00328 | - | - | - |

| Reinforced perforated stainless steel shelf, max. loading 60 kg, with guide bars and fixing screws and only in connection with option K1) | - | - | - | B32191 | B32549 | - | - |

| Stainless steel slide-in drip tray, 15 mm rim (may affect the temperature distribution) - cannot be used in connection with option K1 | E02073 | E29726 | E29726 | E02075 | B32599 | - | - |

| Stainless steel slide-in drip tray, 15 mm rim, with guide bars and fixing screws (may affect the temperature distribution) - can be used only in connection with option K1 | - | - | - | B32763 | - | - | - |

| Stainless steel bottom drip tray, 15 mm rim (may affect the temperature distribution) - cannot be used in connection with option K1 | B04359 | B29722 | B29722 | B04362 | B29769 | - | - |

| Stainless steel bottom drip tray, 15 mm rim (may affect the temperature distribution) - can be used only in connection with option K1 | - | - | - | B34055 | - | - | - |

| Holder for water tank (sizes 110 - 750: 2.5 litres, sizes 1060/1400/2200: 10 litres) for mounting on the rear of the appliance. Standard equipment for sizes 410, 750, 1060, 1400 and 2200. | B49092 | B49092 | - | - | - | - | - |

| Central water supply with filter cartridges for connection to the domestic water supply. Product information on demand. | ZWVR6 | ZWVR6 | ZWVR6 | ZWVR6 | ZWVR6 | ZWVR6 | ZWVR6 |

| Central water supply without filter cartridges for connection to the domestic water supply (only for demineralised water with a conductivity of 5 to 10 μS/cm and a pH value between 5 and 7). Product information on demand | ZWVR7 | ZWVR7 | ZWVR7 | ZWVR7 | ZWVR7 | ZWVR7 | ZWVR7 |

| Max. loading per slide-in drip tray (kg) | 3 | 4 | 4 | 8 | 8 | - | - |

| Max. loading per bottom drip tray (kg) | 3 | 4 | 4 | 8 | 8 | - | - |

| Guarantee extension by 1 year | GA2Q5 | GA3Q5 | GA3Q5 | GA3Q5 | GA4Q5 | GA4Q5 | GA4Q5 |

| USB-Ethernet adapter | E06192 | E06192 | E06192 | E06192 | E06192 | E06192 | E06192 |

| Ethernet connection cable 5 m for computer interface | E06189 | E06189 | E06189 | E06189 | E06189 | E06189 | E06189 |

| USB User-ID stick (with User-ID licence): Oven-linked authorisation licence (User-ID-programme) on Memory-stick, prevents undesired manipulation by unauthorised third parties. When reordering please specify serial number (only for units with TwinDISPLAY) | B33170 | B33170 | B33170 | B33170 | B33170 | B33170 | B33170 |

| Set of height adjustable feet (4 pcs) | B29768 | B29768 | - | - | - | - | - |

| Stacking set (4 pcs) for stacking of appliances of same size | B29744 | - | - | - | - | - | - |

| Flush-fit unit (stainless steel frame covering gap between oven and wall opening), with air slots – technical clarification required | B29734 | B29738 | B42116 | B29742 | B29742 | - | - |

| Flush-fit unit (stainless steel frame covering gap between oven and wall opening), without air slots – technical clarification required | B29735 | B29739 | B42117 | B29743 | B29743 | - | - |

| Subframe, adjustable in height (size 30 to 75: height 600 mm, size 110 to 450: height 500 mm) | B29749 | B29751 | - | - | - | - | - |

| Subframe, on castors (size 30 to 75: height 660 mm, size 110 to 160: height 560 mm) | B29750 | - | - | - | - | - | - |

| Subframe, adjustable in height (height 130 mm, for example for units with fresh-air filter) | B33661 | B33664 | - | - | - | - | - |

| FDA conforming software AtmoCONTROL (FDA edition). Meets the requirements for the use of electronically stored data sets and electronic signatures as laid down in Regulation 21 CFR Part 11 of the US Food and Drug Administration (FDA). Base licence for the control of one unit. Respective IQ/OQ documents available in German and English language (without surcharge) | FDAQ1 | FDAQ1 | FDAQ1 | FDAQ1 | FDAQ1 | FDAQ1 | FDAQ1 |

| Integration of one additional unit (up to max. 31 units) into an already existent FDA-software licence (only for units with TwinDISPLAY) | FDAQ2 | FDAQ2 | FDAQ2 | FDAQ2 | FDAQ2 | FDAQ2 | FDAQ2 |

| External measuring instrument with sensors for daylight and UV-light. Product information on demand (models HPP, ICH L, IPPplus) | B04713 | B04713 | B04713 | B04713 | - | - | - |

| External measuring instrument with sensors with additional measuring head for temperature and humidity measurement. Product information on demand (models HPP, ICH, ICH L, ICH C, IPPplus and ICOmed) | B04714 | B04714 | B04714 | B04714 | B04714 | B04714 | B04714 |

| DAkkS calibration for one (freely selectable) temperature and humidity value according to method C (DKD-R 5-7) | E48847 | E48847 | E48847 | E48847 | E48847 | E48847 | E48847 |

| DAkkS calibration for further temperature and humidity values according to method C (DKD-R 5-7) | E48848 | E48848 | E48848 | E48848 | E48848 | E48848 | E48848 |

| IQ document with device-specific works test data, OQ/PQ check list as support for validation by customer | D00124 | D00124 | D00124 | D00124 | D00124 | D00124 | D00124 |

| IQ/OQ document with works test data for chamber, incl. temperature distribution survey for one free-selectable temperature value. 9 measuring points (size 30), 27 measuring points (sizes 55 - 1060) to DIN 12880:2007-05 (further temperature values on demand), PQ check list as support for validation by customer | D00125 | D00127 | D00127 | D00127 | D00127 | D00127 | D00127 |

| IQ/OQ document with device-specific works test data for one free-selectable temperature and humidity value, incl. temperature distribution survey at Memmert for 27 measuring points (26 measuring points on model HPP1400) to DIN 12880:2007-05, PQ check list as support for validation by customer (models HPP and ICH). | D00136 | D00136 | D00136 | D00136 | D00136 | D00136 | D00136 |

| IQ/OQ document with device-specific works test data for one free-selectable temperature and humidity value, and measuring of light intensity, incl. temperature distribution survey at Memmert for 27 measuring points to DIN 12880:2007-05, PQ check list as support for validation by customer. Price for validation at customer site on demand (GER, AT, CH only) | D00137 | D00137 | D00137 | D00137 | - | - | - |

| On-site IQ/OQ for a freely selectable temperature and humidity value, including temperature distribution survey for 27 measuring points (sizes 110 - 1060, 2200) and 26 measuring points (size 1400) to DIN 12880: 2007-05 (excluding travel costs, not subject to discount, GER, AT, FR only) | DLQ101 | DLQ101 | DLQ101 | DLQ101 | DLQ101 | DLQ101 | DLQ101 |

| Extension of DLQ101 by an additional freely selectable temperature and humidity value (not subject to discount) | DLQ101A | DLQ101A | DLQ101A | DLQ101A | DLQ101A | DLQ101A | DLQ101A |

| Individual on-site Performance Qualification (PQ) | DLQ200 | DLQ200 | DLQ200 | DLQ200 | DLQ200 | DLQ200 | DLQ200 |

| Maintenance HPPeco - carrying out and documentation according to Memmert maintenance plan (excluding travel costs, not subject to discount, GER, AT, FR only) | S00314 | S00314 | S00314 | S00314 | S00314 | S00314 | S00314 |

| Maintenance contract HPPeco - carrying out and documentation according to Memmert maintenance plan, minimum duration 3 years (excluding travel costs, not subject to discount, GER, AT, FR only) | S00314J | S00314J | S00314J | S00314J | S00314J | S00314J | S00314J |

| Calibration of one freely selectable temperature value (excluding travel costs, not subject to discount, GER, AT, FR only) | S00205 | S00205 | S00205 | S00205 | S00205 | S00205 | S00205 |

| Calibration of an additional temperature value (not subject to discount) | S00215 | S00215 | S00215 | S00215 | S00215 | S00215 | S00215 |

| Calibration of one freely selectable temperature and humidity value (excluding travel costs, not subject to discount, GER, AT, FR only) | S00207 | S00207 | S00207 | S00207 | S00207 | S00207 | S00207 |

| Calibration of an additional temperature and humidity value (not subject to discount) | S00216 | S00216 | S00216 | S00216 | S00216 | S00216 | S00216 |

Introducing Peltier App

Redefining Energy Efficiency in Equipment Temperature Control!

Individual Customizations for Specialized Applications

With Memmert m360 we are able to customize our equipment from small modifications to high-tech innovations to meet your exact requirements.