Drying Ovens

Drying ovens are used in manufacturing to remove moisture in products such as textiles, food, and pharmaceuticals at precisely controlled temperatures to reduce the opportunity for mold & bacteria growth and to extend shelf life.

Model Guide

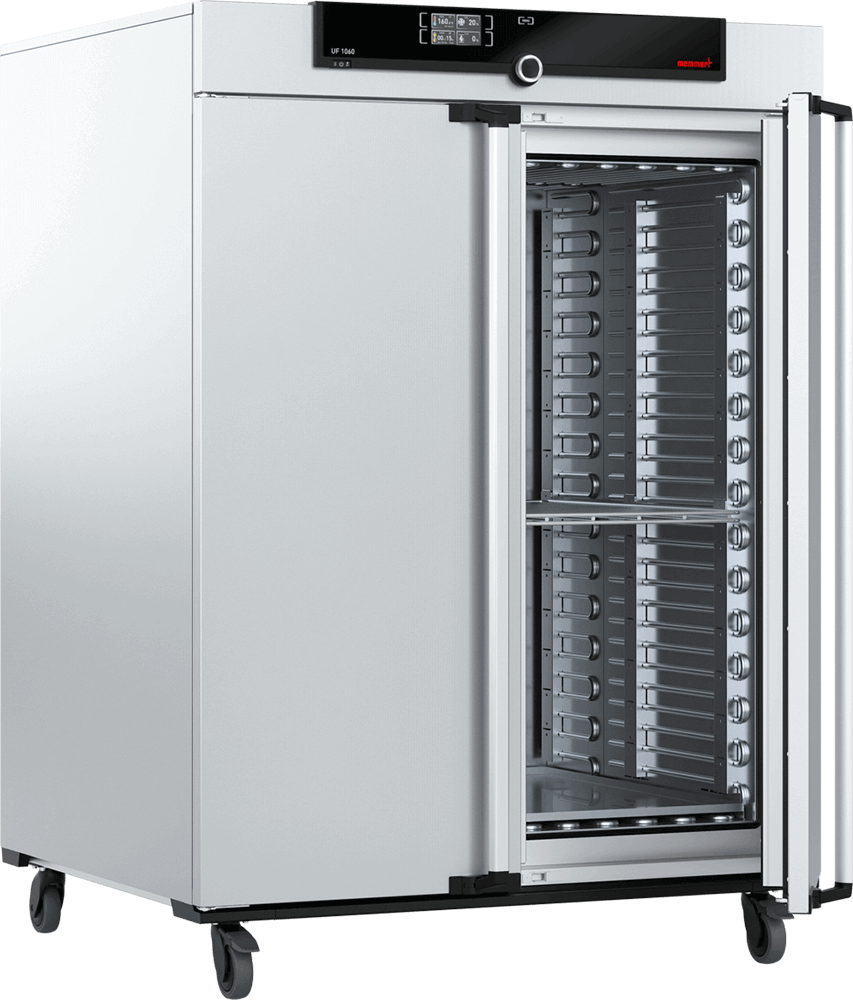

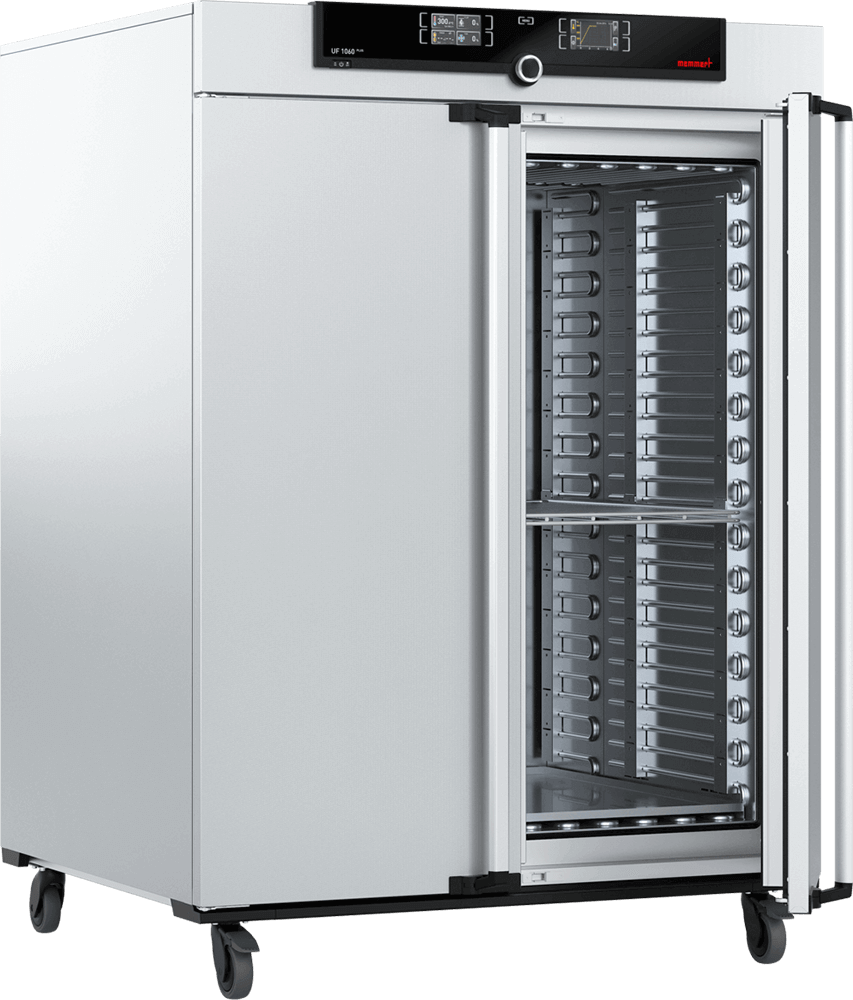

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

UN

Natural Convection Oven

Memmert’s natural convection ovens are designed to reach temperatures up to 300°C efficient for complex processes with sensitive loads, or routine drying and sterilization tasks.

Industry Benefits of Drying Ovens

Using a drying oven increases productivity by speeding up drying times and allowing productions to continue at steady temperatures in industrial baking ovens, rather than productions needing to alter temperatures in one machine to dry products then return to standard temperature. Drying ovens improve the appearance, texture and functionality of products across various industries.

The Memmert universal drying oven stands for unparalleled precise, uniform, and gentle temperature control. Memmert drying ovens have an easy-to-use operating menu, making temperature and air exchange ramps easily programmable via AtmoControl software (available in models with TwinDISPLAY).

Energy Efficiency in Modern Drying Ovens

Modern drying ovens are designed with energy efficiency in mind to help lower operation costs & environmental impact. Many models now incorporate the following:

- Advanced insulation materials and heat recovery systems to minimize energy loss.

- Variable speed fans for optimized airflow and reduced power consumption (when full capacity isn't needed).

- Smart controls to automatically adjust temperature and fan speed based on the moisture content of materials being dried.

Specialized Drying Ovens for Sensitive Materials

Certain materials require carefully controlled drying conditions to prevent damage. For example, pharmaceutical products and electronic components can be sensitive to rapid temperature changes or excessive heat. Specialized drying ovens offer precise temperature ramping, uniform heat distribution and low-turbulence airflow. Some Memmert models also provide inert gas purging capabilities to create an oxygen-free environment, preventing oxidation of sensitive materials during the drying process.

Integration of IoT and Data Logging in Drying Ovens

The latest drying ovens are embracing Internet of Things (IoT) technology to enhance monitoring and control capabilities. Smart ovens can be connected to facility networks to allow remote monitoring and adjustment of drying parameters. Built-in data logging systems record temperature profiles, humidity levels and cycle times, providing valuable data for process optimization and quality control. Some models even offer predictive maintenance features, alerting operators to potential issues before they cause downtime.

Customizable Drying Solutions for Every Industry

Manufacturers now offer tailored drying oven solutions to meet unique industry requirements, enhancing efficiency and product quality. By collaborating closely with customers, manufacturers can tailor chamber size, airflow patterns and control systems to address specific challenges and requirements, helping companies maintain a competitive edge.

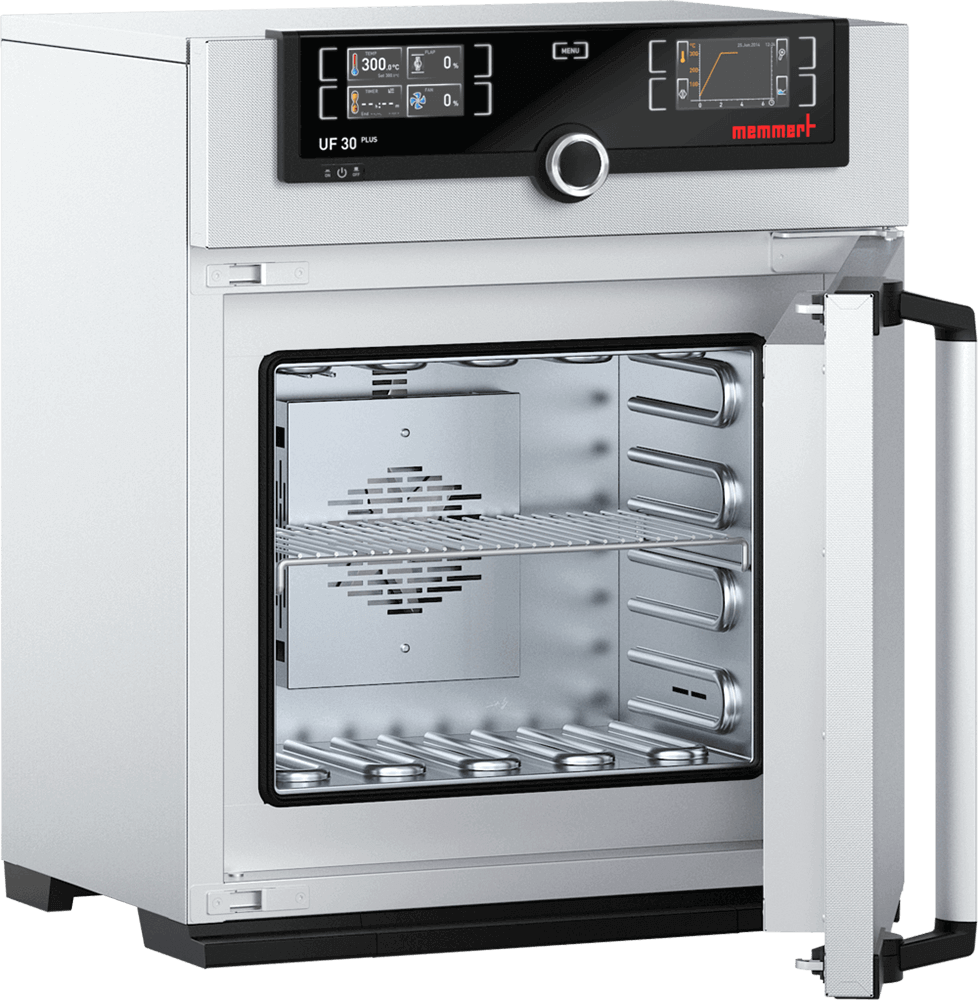

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB