Memmert USA News

Memmert products are engineered and manufactured to achieve the absolute best results no matter your laboratory product needs. We are passionate about precision, reliability, and flexibility. This is the basis on which we set standards for product development, production, distribution, and service.

Memmert USA, LLC is a master distribution source of Memmert products throughout North America. We work directly with the Memmert headquarters in Buchenbach, Germany. It is our responsibility to uphold the highest quality products and service under the Memmert name in all aspects of our business.

Get the latest updates on our team below.

Featured Post

Memmert USA is thrilled to announce the official launch of a strategic partnership with Aralab, marking a significant milestone in our commitment to delivering quality, reliability, and precision engineering to our customers. This collaboration pairs Memmert’s legacy of excellence with Aralab’s specialized expertise, aiming to provide unparalleled value to clients in the USA and beyond. Engineered for versatility and performance, Aralab Walk-In Chambers are meticulously designed to meet the rigo... Read More

Recent Posts

Why is Memmert’s ICO incubator the perfect combina...

The success of tissue culture experiments hinges on one key factor: maintaining an ideal environment. That’s w... Read More

How Memmert Equipment is So Quiet, You Don’t Need ...

If you’ve ever worked in a lab, you may be familiar with the constant hum of equipment running in the backgrou... Read More

Collaboration Between Memmert USA and Kaye Enhance...

As the laboratory equipment and validation industry continues to evolve, strong customer-supplier relationsh... Read More

How Memmert Peltier Technology Can Help Soothe, Pr...

When it comes to the precise and reliable storage of sensitive samples, researchers, laboratories, and industr... Read More

Aralab and Memmert Forge Strategic Partnership to ...

SCHWABACH, GERMANY / SINTRA, PORTUGAL — Memmert GmbH + Co. KG, a global leader in climate and temperature cont... Read More

Understanding ICH Stability Testing: Why Memmert E...

Stability testing is a critical aspect of product development and quality control across various industries to... Read More

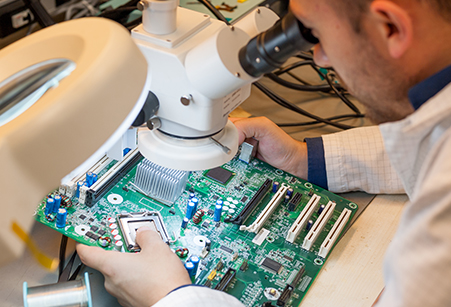

Memmert Equipment in the Electronics Industry

The electronics industry is known for its dedicated processes, stringent requirements and the necessity of pre... Read More