Elevate the precision of NDIR-based CO2 sensor for breath analysis with the Memmert universal oven UF30

A Memmert universal oven UF30 was used in an experiment aimed at enhancing the precision of NDIR-based CO2 sensors for breath analysis. This device is part of Memmert’s series of drying ovens. You can read the full report here.

This study analysed the chemical composition of human exhaled air, which has over 3000 identified gaseous components, many of which are biomarkers for disease at ppb-ppm level. To accurately measure these biomarkers, it is important to minimise the adverse effects of water vapour and changes in exhaled air pressure and temperature.

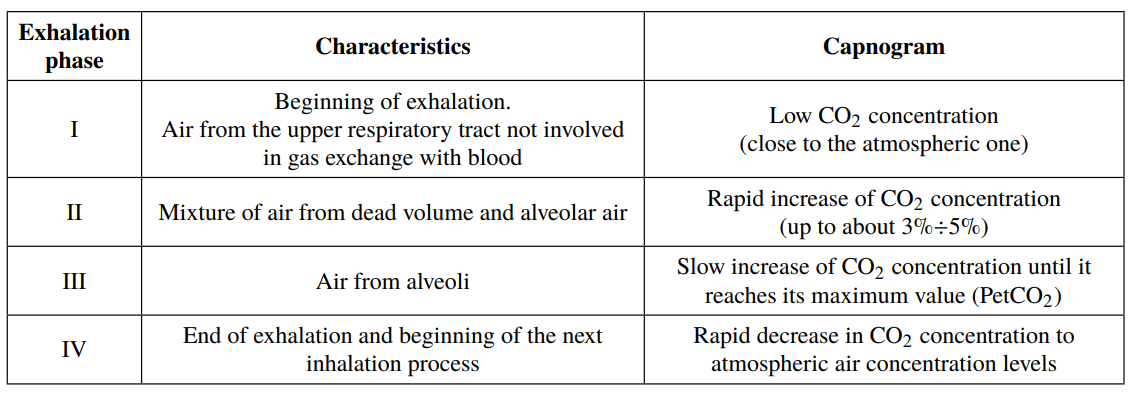

The study focused on the analysis of changes in CO2 concentration during exhalation, which can be shown in a capnography waveform and divided into four phases. The Memmert universal oven UF30, part of the drying oven line, was used in the study.

Exhalation phases determined using exhaled CO2 concentration

Research tasks and methods

Sensor analytical model

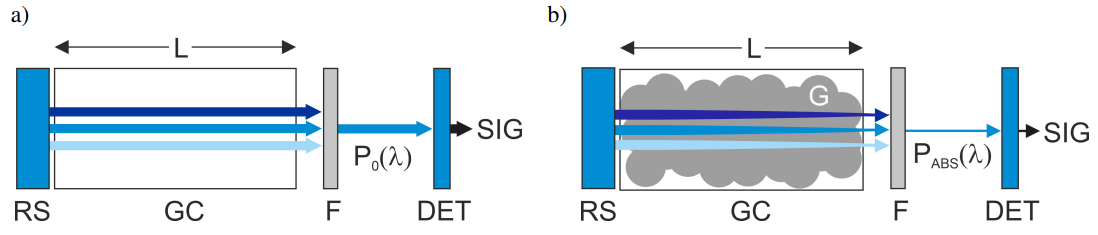

In the study, the performance of a nondispersive infrared (NDIR) type CO2 sensor was analysed to determine the accuracy of the CO2 concentration measurements.

Components of the NDIR sensor: P0 (λ) is the radiation power incident on the detector with absence of gas in the gas cell (a), PABS (λ) is the radiation power incident on the detector when the test gas is present in the gas cell (b)

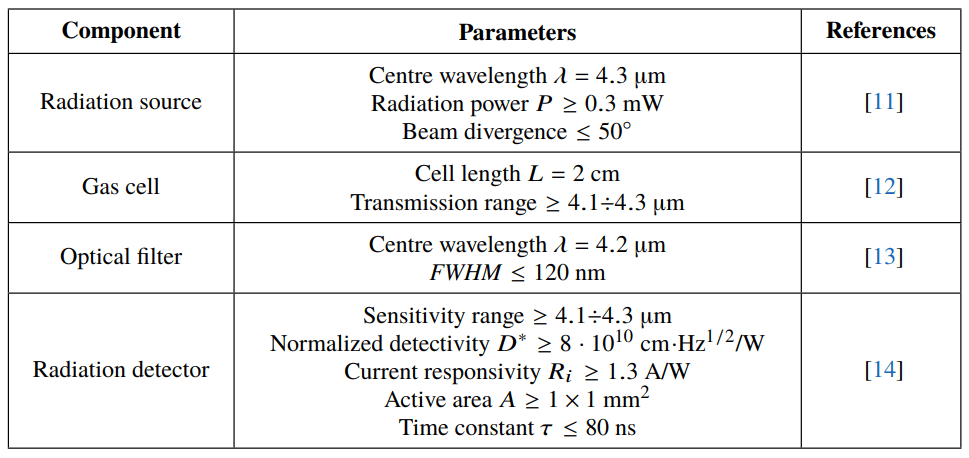

The sensor was modelled theoretically and the spectral characteristics of radiation absorption were determined. The absorption spectra were analysed using Hitran-PC software and simulations were carried out to identify the basic phenomena in the NDIR sensor.

Main parameters of the NDIR sensor model components

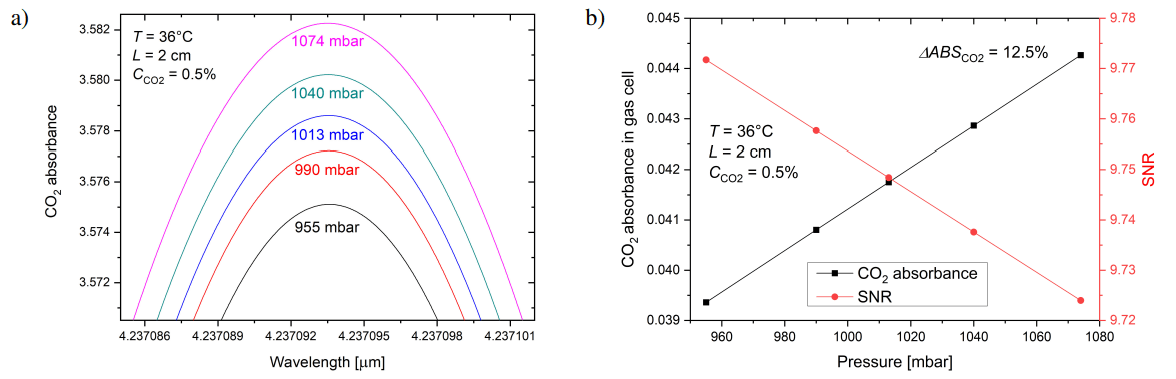

The analysis was performed for different pressures and temperatures to estimate the influence of these parameters on the accuracy of the NDIR sensor. The results of the analysis showed that human exhaled air absorbance and signal-to-noise ratio (SNR) were affected by the pressure and temperature, thus affecting the accuracy of the NDIR sensor.

Analysis of the influence of pressure and temperature

The noise level of a detector was calculated using thermal noise current and the noise equivalent power was determined.

CO2 absorbance changes on the selected gas absorption line (a), CO2 absorbance in the gas cell and SNR as a function of human exhaled air pressure (b)

The signal-to-noise ratio was found to be 17.85 dB. The influence of CO2 concentration was analysed and found to affect the absorbance of the gas, but not the signal-to-noise ratio by a significant amount (less than 0.5%).

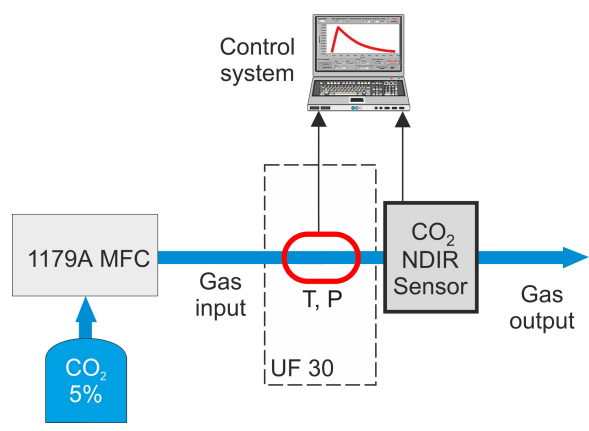

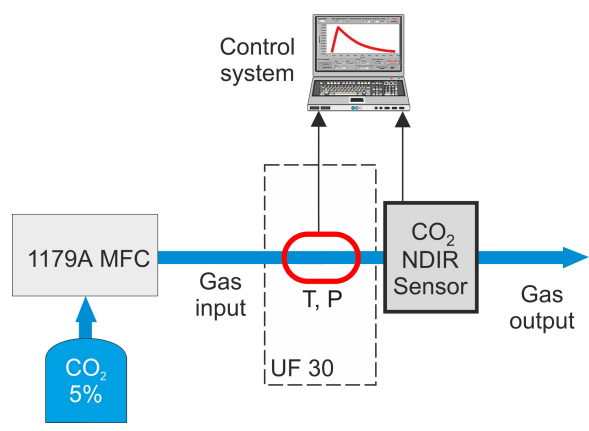

Experimental setup for testing the CO2 sensor. T – temperature sensor, P – pressure sensor

The experiments were carried out using a Memmert universal oven UF30, an MKS Type 1179A mass flow controller, a BMP280 pressure and temperature sensor, and a UTECH UT100C ETCO2 sensor. The correction functions were evaluated using OriginPro 2020 software.

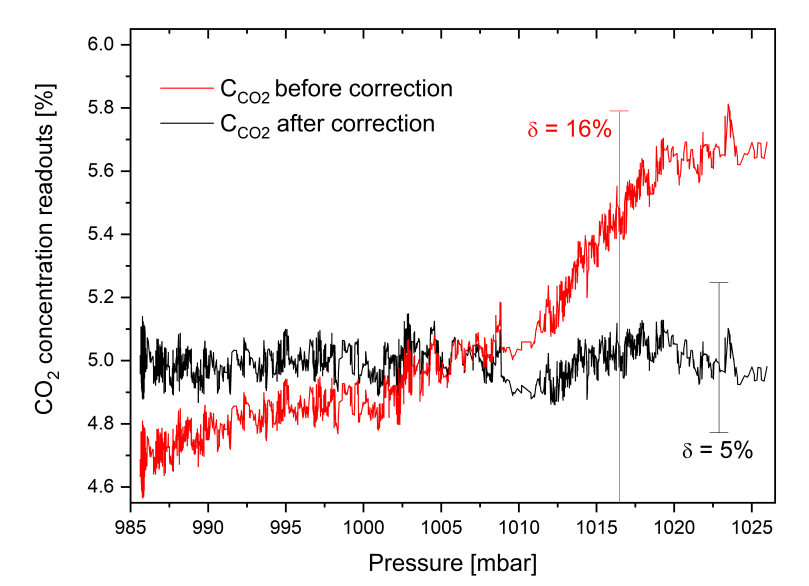

Pressure influence on the UT100C CO2 sensor readouts before and after correction

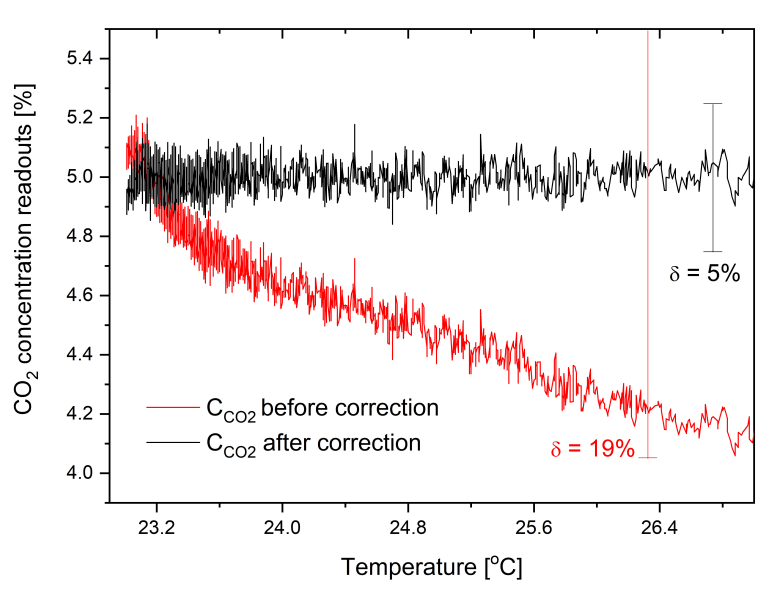

Temperature influence on UT100C CO2 sensor readouts before and after correction

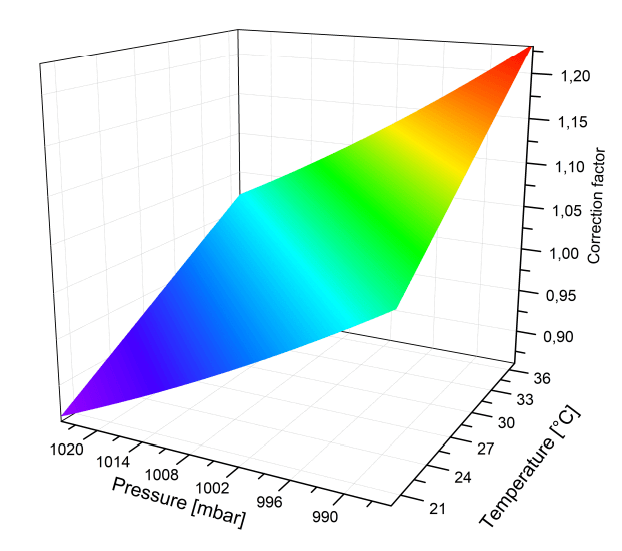

Correction factors for pressure and temperature influence on CO2 sensor measurements

Conclusion

The NDIR CO2 sensors are used to measure the concentration of carbon dioxide exhaled by patients, but the pressure and temperature of the air flowing through the sensor are not always measured. This leads to incorrect readings. To correct these readings, a correction of the influence of pressure and temperature was carried out on the UT100C CO2 sensor. The correction factors reduced the relative uncertainty of the measurements from 19% to less than 5%. This is an important consideration for any NDIR CO2 sensor analysis, as analogous phenomena are likely to occur. The correction process was demonstrated both theoretically and experimentally and used the Memmert universal oven UF30, a device from the drying oven series.

About the Memmert universal oven

The Memmert universal oven is a device from Memmert’s series of drying SingleDISPLAY and TwinDISPLAY. The oven offers a temperature scope of up to +300°C and users can choose between natural convection or forced air circulation. The oven is simple to operate with an intuitive menu and features programmable temperature and air exchange ramps as well as a pre-heated fresh air system that prevents temperature fluctuations.

The oven is made from high-quality, corrosion-resistant stainless steel and offers a range of options for programming and documentation using interfaces, integrated data logger and AtmoCONTROL software. It also comes with a 3-year worldwide guarantee. Additionally, the Um model can be used as a medical device for heating fango, silicate and APS packs for physical therapy.